Make all product and manufacturing information more transparent.

A passport for the entire product lifecycle will be launched in the context of the government’s digital policy agenda for the environment. The Supply Chain Act also comes into force this year. This increases the pressure on companies to make data accessible and to take a closer look at the value chain of their products and services in the interest of a circular economy. But what could a solution look like? And what benefits do you derive from the transparency you have created?

General background information on the digital product passport and the requirements can be found in our blog post.

When companies implement a digital product passport, they associate the “digital twin” with various concepts and expectations. The critical systems are interconnected, and all master and transaction data, e.g., from machines and systems, measurement data, and material information, are collected in one place. This virtual image provides the basis for the digital product passport.

An integrated sensor can make every machine in the factory a smart object. If each sensor is connected to the internet, all data and information flow into the digital twin. This includes external data from suppliers, weather conditions, or delivery terms.

“From a technical point of view, all necessary internal and external systems are connected via a central point. All data and information converge there: product components, materials, (chemical) substances, sustainability (lifecycle CO2 emissions), and after-sales information (disposal/recycling, disassembly instructions, and reparability). Subsequently, the desired information is visible and can be retrieved by the target group via a digital interface.”

Eduard Daoud, Sales Director TRANSCONNECT

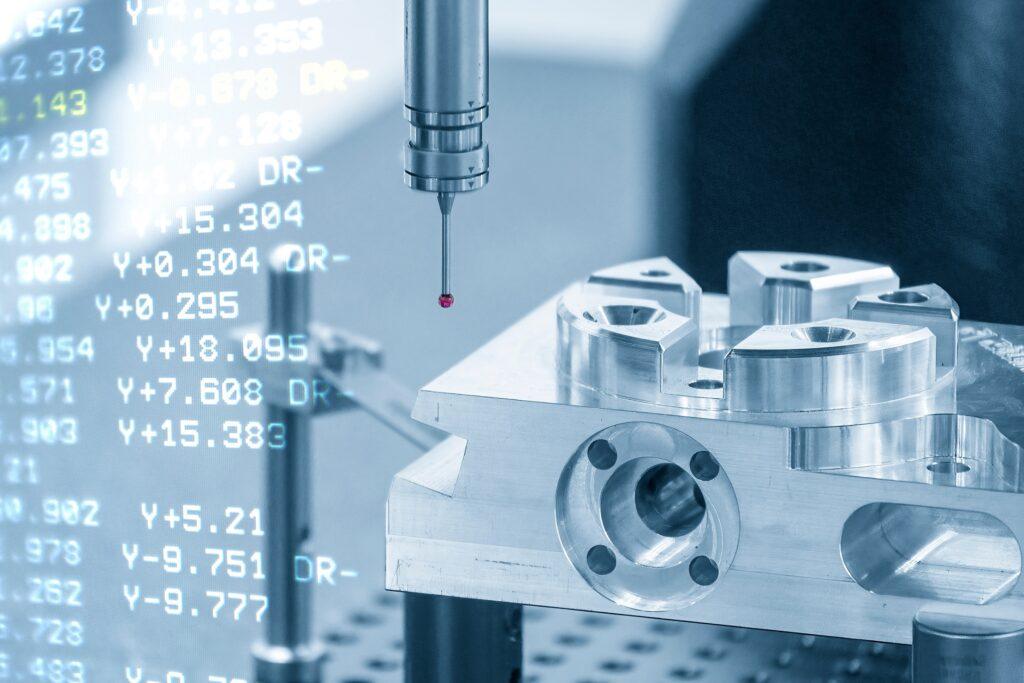

A highly specialised company manufactures high-quality parts for aerospace and robotics. Custom-made products with special dimensions are later used under extreme temperatures and high speeds. The company must “prove” that the required quality of the products corresponds to reality. B2B customers wish to see all the information about the items they order at any time. For this purpose, the TRANSCONNECT® team has created an integration platform that intelligently links the company’s critical systems, such as ERP, MES, or databases via coherent interfaces. All master and transaction data of the products, such as measurement data and information on production, weight, tolerances, or standard deviations at the individual measuring facilities and systems, now converge in one place. The information is validated and mapped in a digital directory. This virtual image of the real data and production processes forms the digital twin of production.

Subsequently, these data sheets, production and quality information, and measurement curves are made transparent and accessible in an information and service portal. It gives all B2B customers access to all product and manufacturing information.

The objective of structuring the data from all stakeholders along the value and supply chain is, among other things …

Don’t miss any news.

Ask any question.

Exchange ideas with us.

Don’t miss any news.

Ask any question.

Exchange ideas with us.

Wir unterstützen Sie bei der Umsetzung mit maßgeschneiderten Bausteinen, um eine zukunftsorientierte und bürgerzentrierte Verwaltung zu gestalten.

Lorem Ipsum

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.